Two Day DIY Barn Door Build!

We needed a closet door for the bedroom and there isn’t really room for a normal door so we decided on a barn door. I figured I would take you guys a long for this budget minded two day build! Hope you enjoy!

Special thanks to Home Depot for inviting me to be part of the PRO-Spective program and for sponsoring this build!

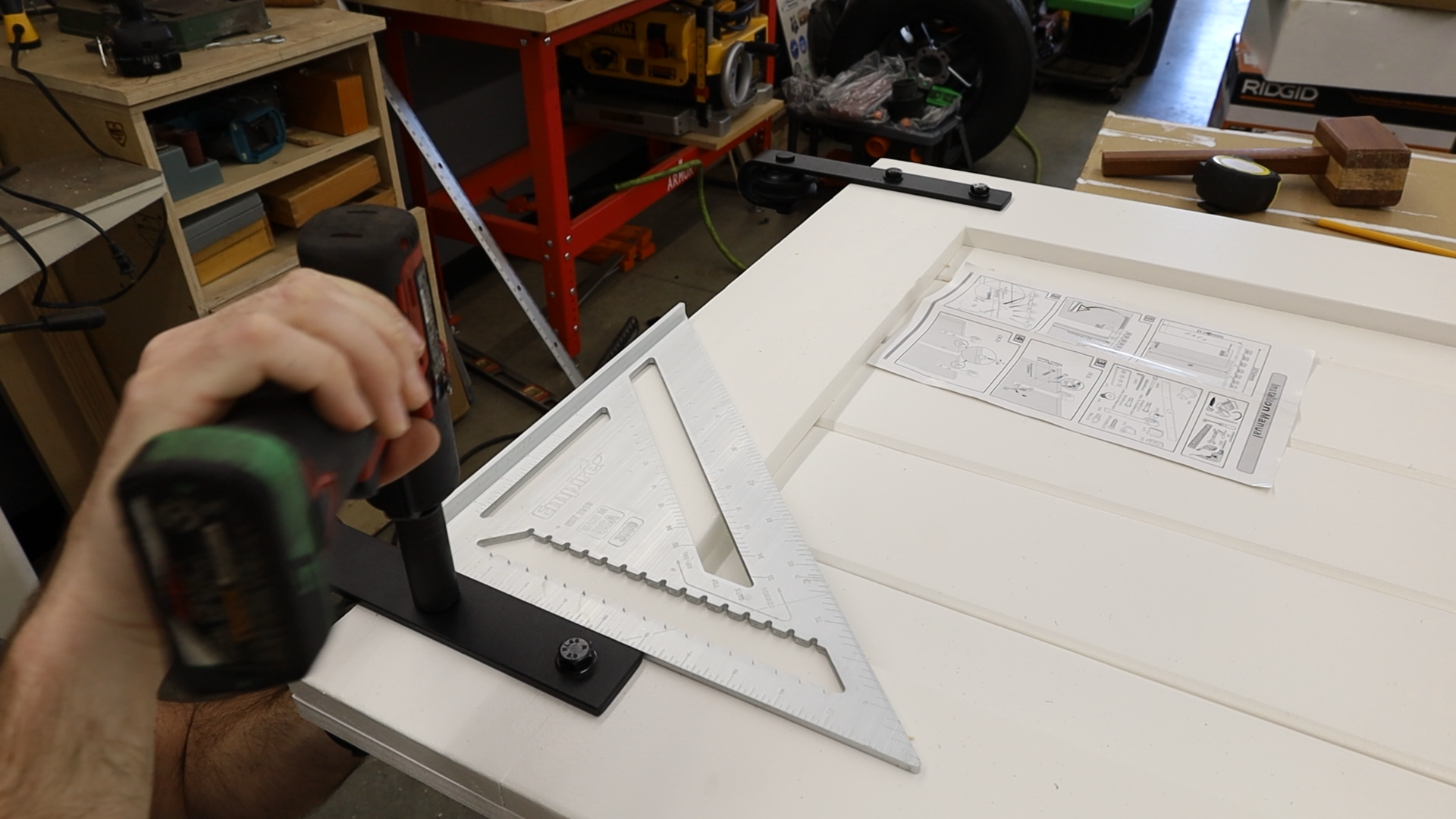

Provided tools used in this build:

Ryobi ONE+ HP 18V Brushless Cordless 7-Tool Combo Kit with (2) 2.0 Ah Batteries, Charger and (2) Bags -