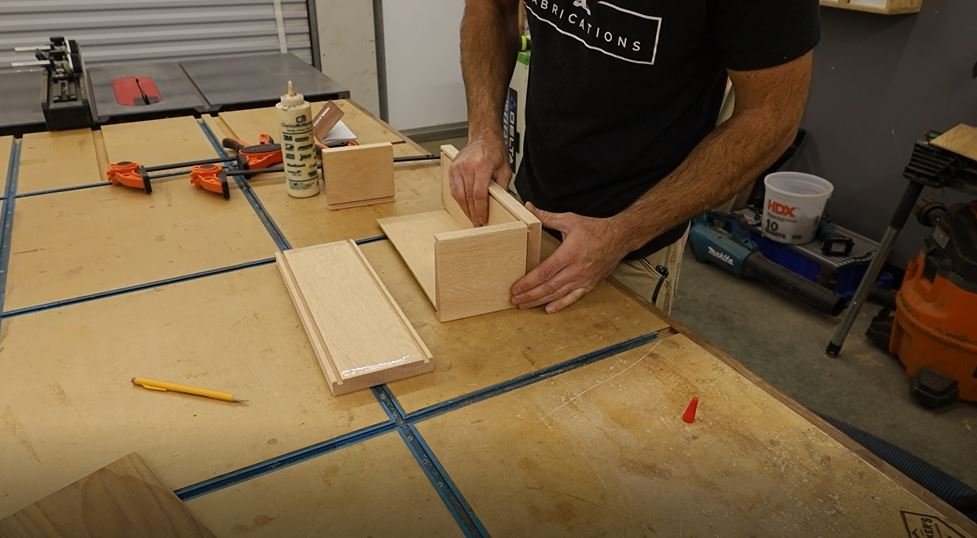

3 Projects You Can Gift Or Sell!

I wanted to show you guys some of the projects I make around the holidays to give as gifts or to sell! I came up with 3 that I think go over very well and most people will love. Be sure to check out the full video for a better visual.

Special thanks to Home Depot for inviting me to be part of the

PRO-Spective program and for sponsoring this build!

Tools used in this build:

18V Brushless Cordless 4-Tool Combo Kit with (1) 4.0 Ah and (1) 2.0 Ah MAX Output Batteries, 18V Charger, and Tool Bag

http://homedepot.sjv.io/c/3106512/1208548/8154

ONE+ 18V Lithium-Ion Cordless AirStrike 18-Gauge Brad Nailer and 16-Gauge Straight Nailer 2-Tool Combo Kit

http://homedepot.sjv.io/c/3106512/1208549/8154