T-Track Assembly Table/Outfeed Table

I have a small workshop so I wanted to create a central work station that served as many needs as possible. This is what I came up with! It serves as an assembly table, work bench, outfeed table and has tons of storage!

Be sure to check out the build video above!

In this project I go over how I built my assembly table / outfeed table with Rockler T-Track built into the top and edges for awesome clamping options. It also has a lot of storage as well as pull outs for systainers or whatever else you want to put on them! Feel free to adjust the dimensions to fit your needs!

For full detailed build plans - CLICK HERE

Tools and Equipment used in this build (affiliate links included)

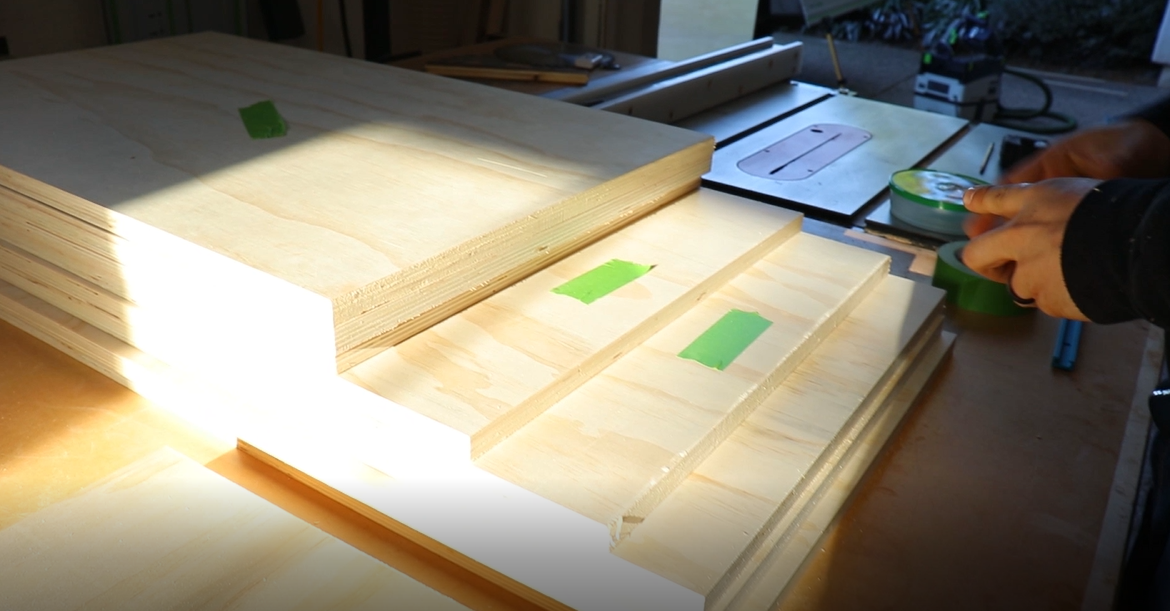

I started out with 2 - 4' x 8' sheets of 3/4" sanded ply and one sheet of MDF. I rough cut them all down to just a little over 6' x 4'.

Then I laminated them all together with glue and screws, making sure the MDF was on top. (I used a flush trim bit in my router after laminating each one to make it all nice and flush.) Side Note - If I were to do this again I would probably just go with all plywood. Personal preference.

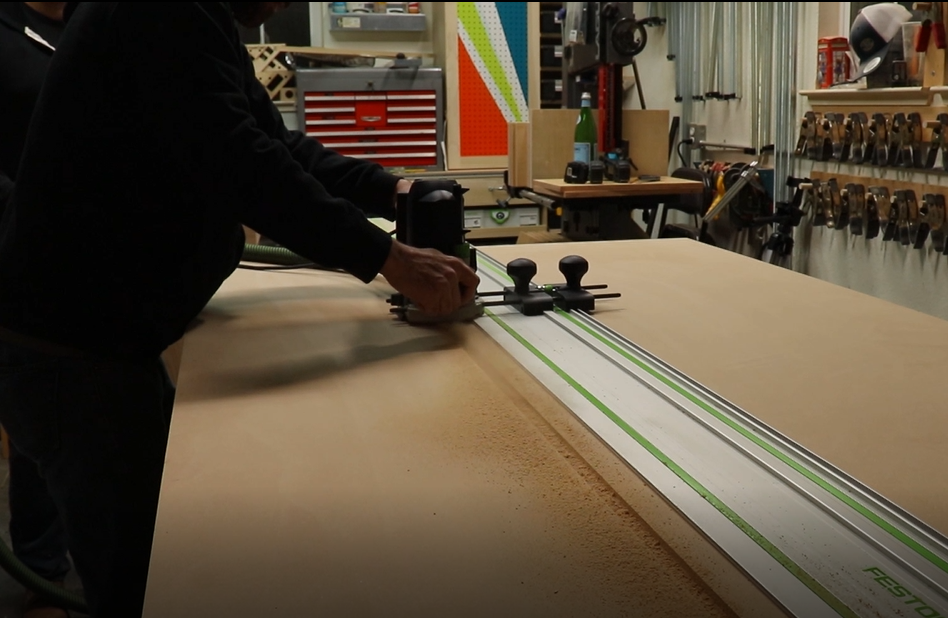

At my buddy Oscar's shop we used a combination of his track saw and table saw to cut all the pieces for the cabinet carcasses.

We made sure to label each one!

I moved onto drilling pocket holes with the Kreg Foreman. (also Oscars) Super quick and easy.

Using a 3/4" bit in Oscar's router I cut the slots for the t-track in 3 depth steps. The cool thing about this system is the router attaches to the track for the track saw. Makes it super simple to keep everything straight.

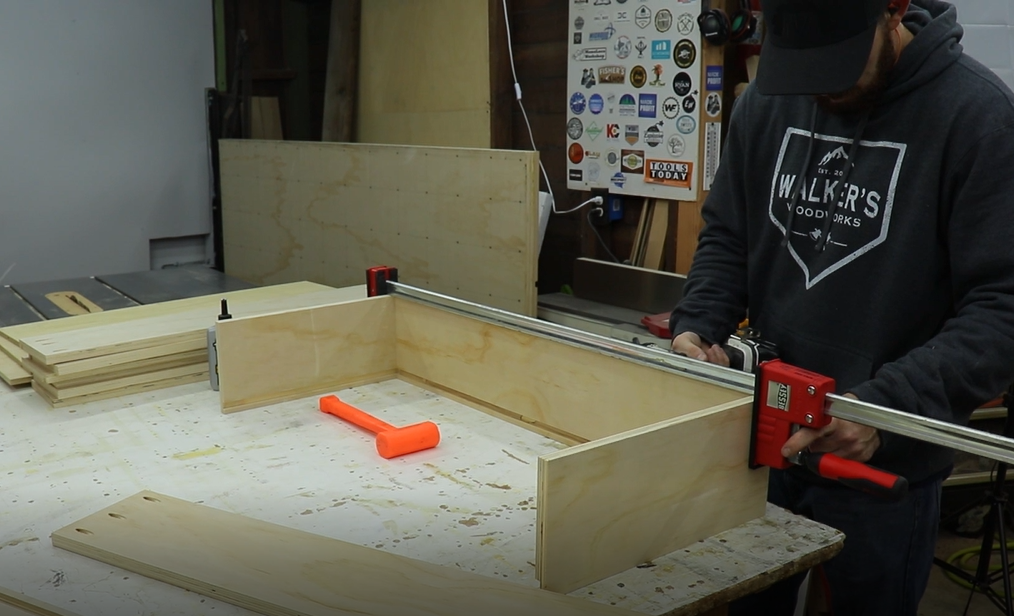

Back at home I started assembling all the cabinet carcasses individually. One side houses pull outs for systainers, the other houses my shop vac/dust separator, and the end cabinet has 4 wide drawers in it.

I then turned my attention to cutting the drawer stock. I used 3/4" ply for the sides, false front and back. I used 1/2" ply for the drawer bottoms. I also used this time to cut the overlay drawer fronts.

A dado stack is a simple way to cut the 1/2" slots in the two sides and back for the drawer bottoms.

Using pocket screws and glue I put the sides and back together then slid the bottom in the dado slot. I then attached the front.

Using spacers I installed the Accuride drawer slides per instructions and then in went the drawers! These are soft close slides and it makes it so nice!

I put a chamfer around all the drawer fronts just to give it a little character.

Then to install the fronts I used glue, spring clamps and screws from the backside.

I cut and installed backs for all the cavities using glue and brad nails.

Using under mount slides I installed the pull outs for the systainers.

I cut the material for the two doors on the cabinet that will house the vac and dust collection. Using this awesome kreg hinge jig I cut the holes for the hinges. This thing works awesome! Also these hinges work really well.

I created an adjustable base for the assembly table and using these adjustable feet worked amazing! I just made it out of the same 3/4" ply I used for the rest of the table putting in bracing and also some pieces to screw the cabinets to once installed.

I cut all the pieces of the T Track and dry fitted it all. I used the pre made intersections which helped a ton! Once it was all dry fit I went over everything with a small round over bit and then installed the t track.

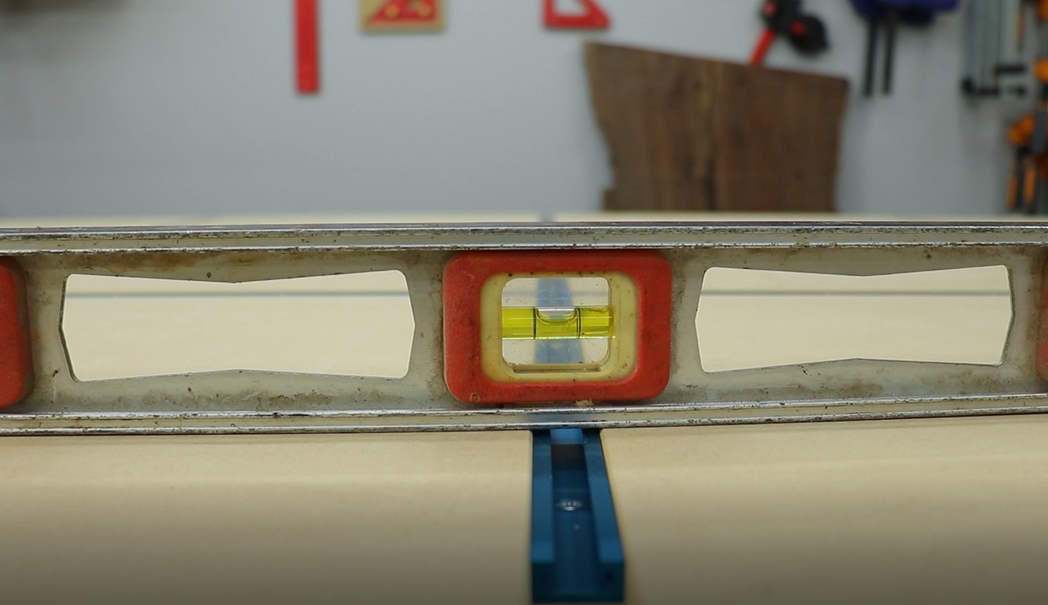

I leveled out the base as well as I could, set the cabinets on it, attached them to it and also screwed them together,

Making sure it was centered I attached the top with screws from underneath all the way around.

I reinstalled the drawers, pull outs and snapped the doors back on.

I decided to use walnut for the edges because I love the way it looks with the blue T Track in it. I did this so I could hold pieces vertically to work on. It works very well. Using my dado stack I cut the 3/4" slot for the track in the trim pieces. I used glue and brad nails to attach the trim.

Cutting the corners off does a couple things... You wont injure yourself running into them and also it allows space for the clamps to slide in and out.

I also used walnut and made my own drawer pulls and pull out fronts. I cut a 45 degree finger hold on the bottom of the pulls.

I didn't capture it but I also used the drawer pulls as the cabinet door handles.

I used boiled linseed oil and it looks really good. HOWEVER, if you do use MDF for the top I would suggest using poly or something else. The linseed oil soaked in really bad and left a kind of uneven finish on the MDF.

Then I could install the T Track on the trim pieces. I decided to only put it on two sides but you can put it all the way around if you would like :)

All in all I really enjoy using this table on a daily basis! I left the systainer area open on the right to add more later. Thanks so much guys for making it to the end. Don't forget to watch the build video for more detail on the build and if you want to build one yourself as well as support me doing what I love consider purchasing the plans I had professionally made. They are VERY detailed and laid out great. Thanks again and I will see you on the next build!

FULL BUILD PLANS - Click for plans